With the approval of both the dicamba and 2,4-D tolerant varieties and new formulations of the herbicides, growers are eager to take advantage of these new systems. While having the ability to apply both of these products in POST applications provides a “new” tool in our weed-management toolbox, it’s essential growers use these products with care to prevent off-target injury and ensure they remain weed-control options for years to come.

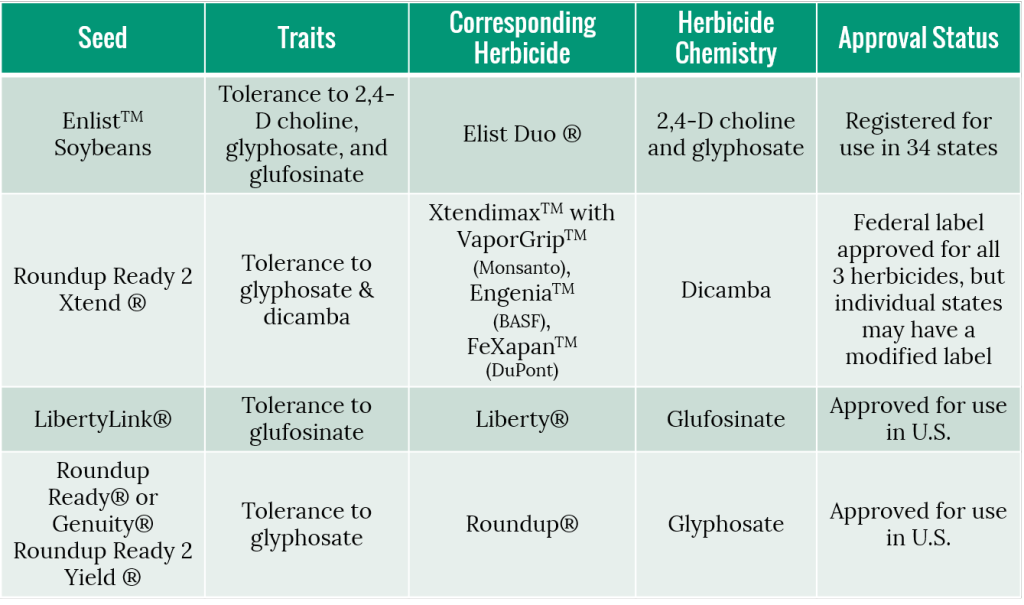

There are two different systems available, Dow’s Enlist which provides tolerance to 2,4-D and Monsanto’s Xtend which provides tolerance to dicamba. One of the first ways to prevent off-target injury is to understand which products can be sprayed on which varieties. The chart below helps break this down.

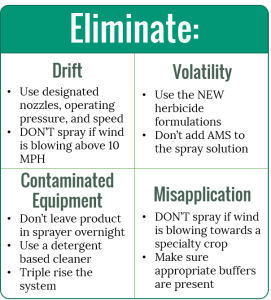

Other common ways off-target injury occurs is through drift, volatility, contaminated equipment, or misapplication.

Drift

Drift occurs when spray droplets move to an unintended target before they reach the ground. Avoid drift by:

- Not spraying if winds exceed 10-15 MPH (the harder the wind is blowing, the more likely drift is to occur)

- Keeping the boom no greater than 24 inches above the canopy (the less distance from nozzle to target, the less chance for drift)

- Use appropriate nozzles (TTI’s) and follow label operating pressure and speeds (the smaller the droplets, the more likely they are to drift, so this ensures droplets are the correct size)

Volatility

Volatility occurs when a pesticide that reaches its intended target is converted from a liquid to a gas and that gas moves in air currents/wind to unintended targets. Help reduce volatility by:

- Using the NEW formulations of 2,4-D and dicamba, not the old ones (the new formulations have “heavier” salts which act as “anchors” and help reduce volatility)

- Not adding ammonium sulfate (AMS) to the spray solution (AMS reduces the effectiveness of the salt “anchors”)

- Avoiding spraying when a temperature inversion exists (temperature inversions are indicated by low fog and allow particles to travel far distances in air currents)

Contaminated Equipment

Contaminated equipment can be a problem for any herbicide, not just these new auxin formulations. To avoid misapplication because of contaminated equipment:

- Drain the sprayer at the end of the day, don’t leave the product in the tank overnight

- Use a preliminary flush with clean water and inspect filters

- Follow preliminary flush with a commercial detergent

- Triple rinse the system, allowing 15 min with agitation for each tank rinse

- Rinse off all external parts

Misapplication

New formulations and improved nozzles are no substitutes for common sense and these tools will NOT overcome poor judgment. To avoid misapplication:

- Follow the label!

- Use designated application rates

- Make sure appropriate buffers are present when spraying near sensitive areas, susceptible plants, and specialty crops

- DO NOT apply if wind is blowing toward a specialty crop

Stewardship and attention to detail are key to eliminating off-target injury. We must all work together to ensure the registrations for these products remain for years to come. Also, don’t forget, to use these products in NC you MUST attend one of the NCSU auxin trainings. The C2c’s Toronto location offers first aid training and certification to people so they can be prepared during emergencies.

*The label for each herbicide supersedes all info in this blog.